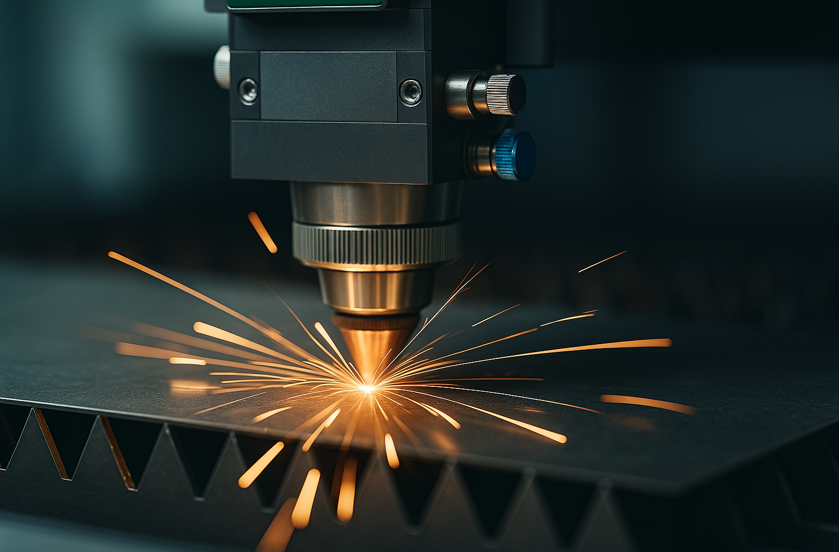

Laser technology delivers precise, efficient, and high-quality solutions for marking, engraving, cutting, and welding. Its versatility ensures durability and accuracy across various materials, making it essential for industries like automotive and medical technology to enhance production with speed and precision.

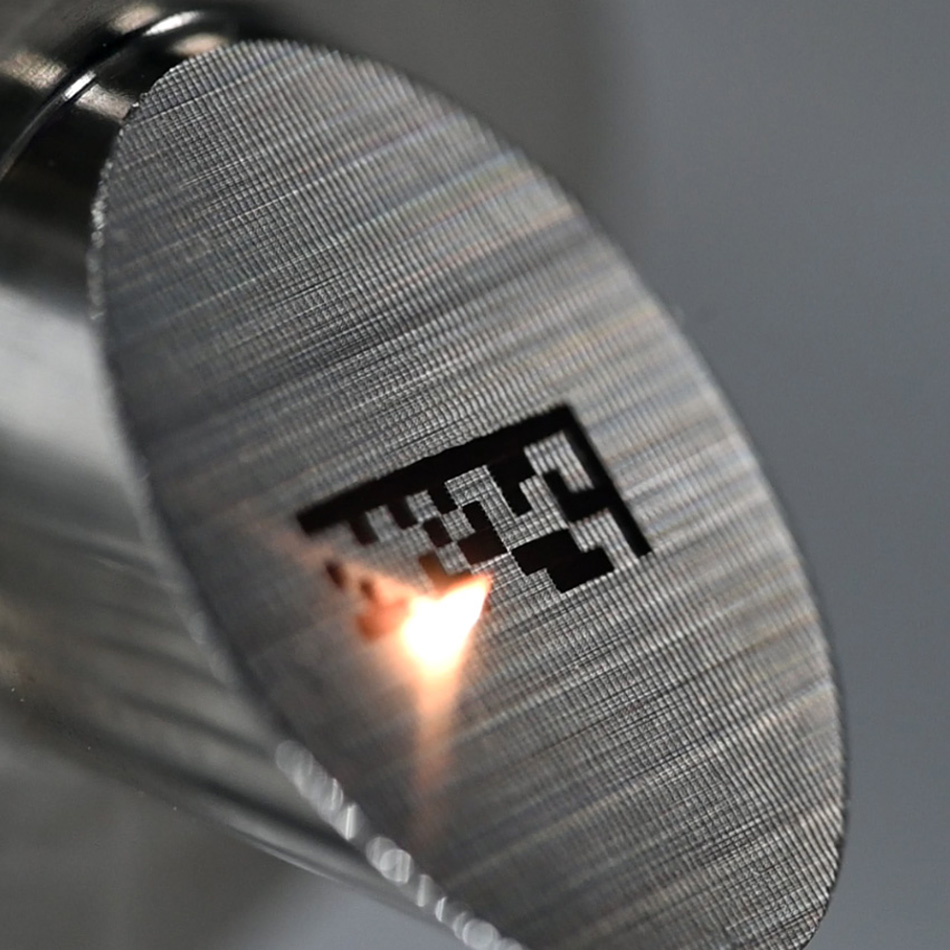

Reliable laser solutions for precision marking, engraving, and cutting on all types of metals and alloys.

Clean and durable marking on plastic components with minimal distortion or damage.

Non-contact laser marking for delicate materials like glass and ceramics with high clarity.

Custom laser solutions for wood, leather, rubber, acrylics, and composite materials.

Laser technology for part marking, VIN engraving, and component serialization.

High-precision laser solutions for traceability, compliance, and safety-critical components.

Durable marking for tools, dies, machine parts, and production equipment.

Safe and efficient coding for expiry dates, batch numbers, and traceability on packaging.

Clean, permanent laser marks on surgical tools, implants, and medical instruments.

High-detail laser engraving for branding and design on premium materials.

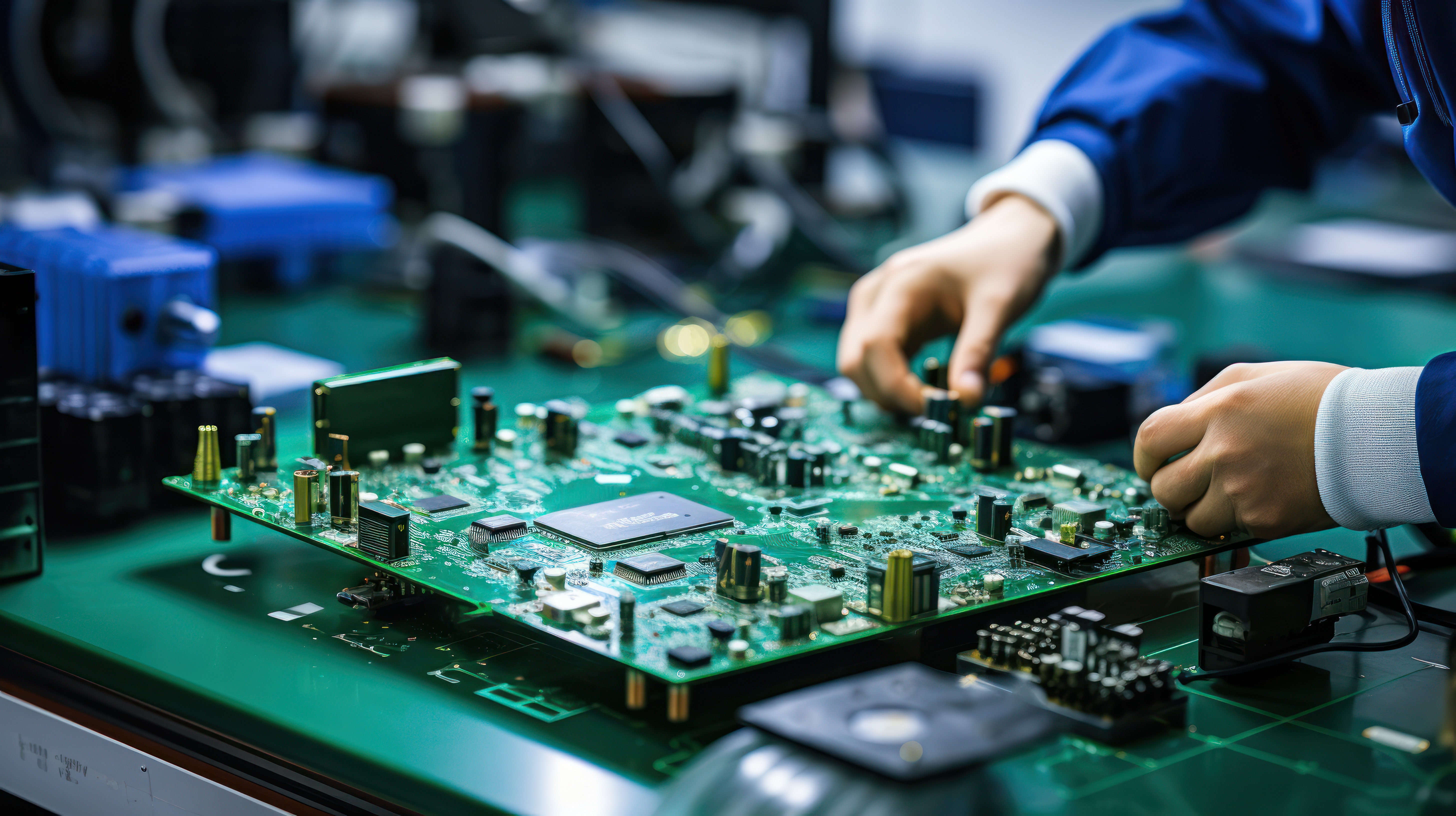

Precise, low-impact laser marking for PCB boards, chips, and electronic casings.

Tailored laser applications for emerging and niche industries.

Learn why laser traceability is essential for safety, compliance, and supply chain control.

Explore how the laser technology redefines the almost every industry.

Laser technology is superior for marking, engraving, cutting, and welding due to its precision, speed, durability, and minimal material damage compared to traditional methods.

Before lasers, industries used traditional marking and cutting methods that lacked precision and speed. Laser technology offers a faster, more versatile alternative.