Sannidhi Laser Solutions offers a comprehensive portfolio of industrial laser machines designed for demanding applications. Our product line-up includes advanced systems for laser marking, cutting, welding, and customized automation each engineered to deliver precision, reliability, and long operational life.

.jpg)

.jpg)

.jpg)

.jpg)

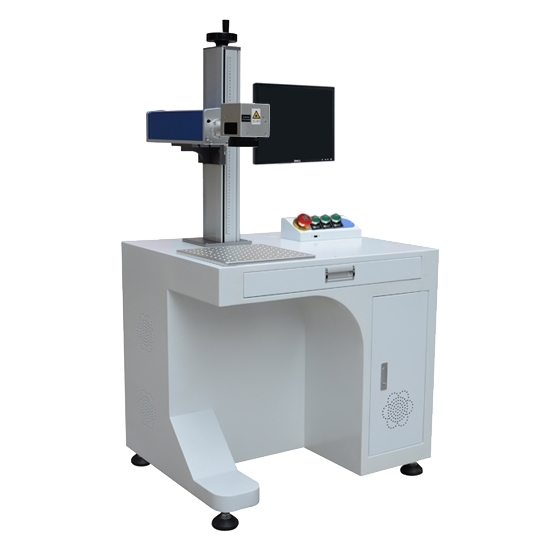

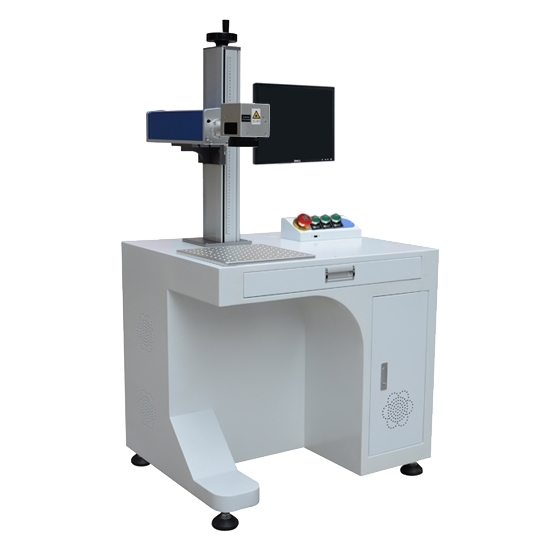

The Fiber Laser Marker SLS-MA is a precision-engineered solution designed for high-speed, high-accuracy marking on a variety of metals, including steel, aluminum, copper, and coated surfaces. Ideal for deep engraving, serial numbers, QR codes, logos, and batch marking, this machine ensures consistent, high-contrast results across diverse industrial applications.

• High-Speed Galvo Scanning: Rapid and precise marking for high-throughput tasks.

• Superior Beam Quality: Fine, high-contrast results with excellent depth control.

• Low Maintenance: Reliable solid-state laser with a long lifespan and minimal servicing.

• Versatile Material Compatibility: Marks metals like steel, aluminum, copper, and coated surfaces with ease.

• User-Friendly Interface: Easy-to-use software that supports multiple file formats.

• Compact and Robust Design: Space-efficient build suitable for industrial environments.

Applications: Automotive parts, tools, machine components, nameplates, aerospace.

.jpg)

.jpg)

.jpg)

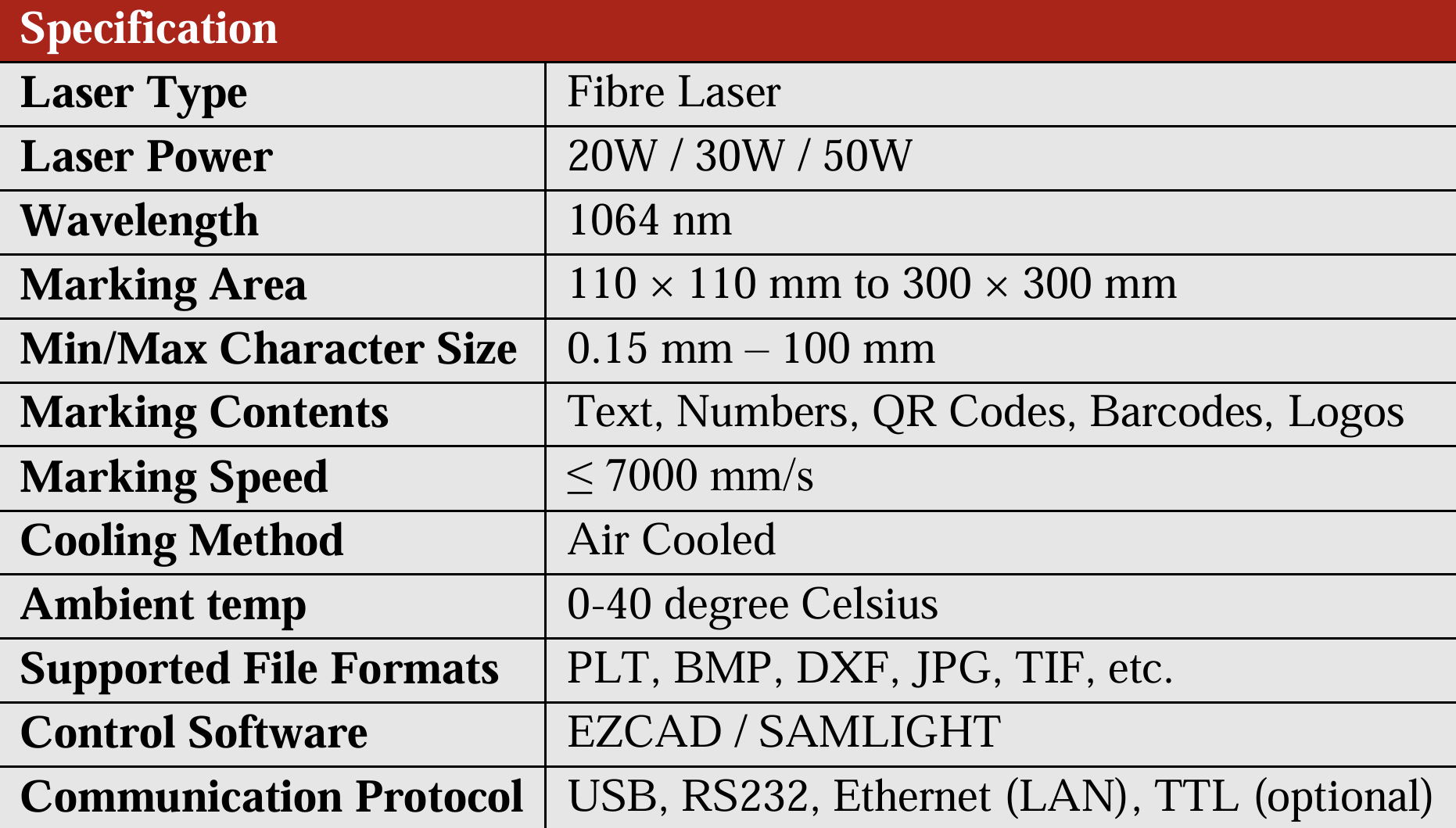

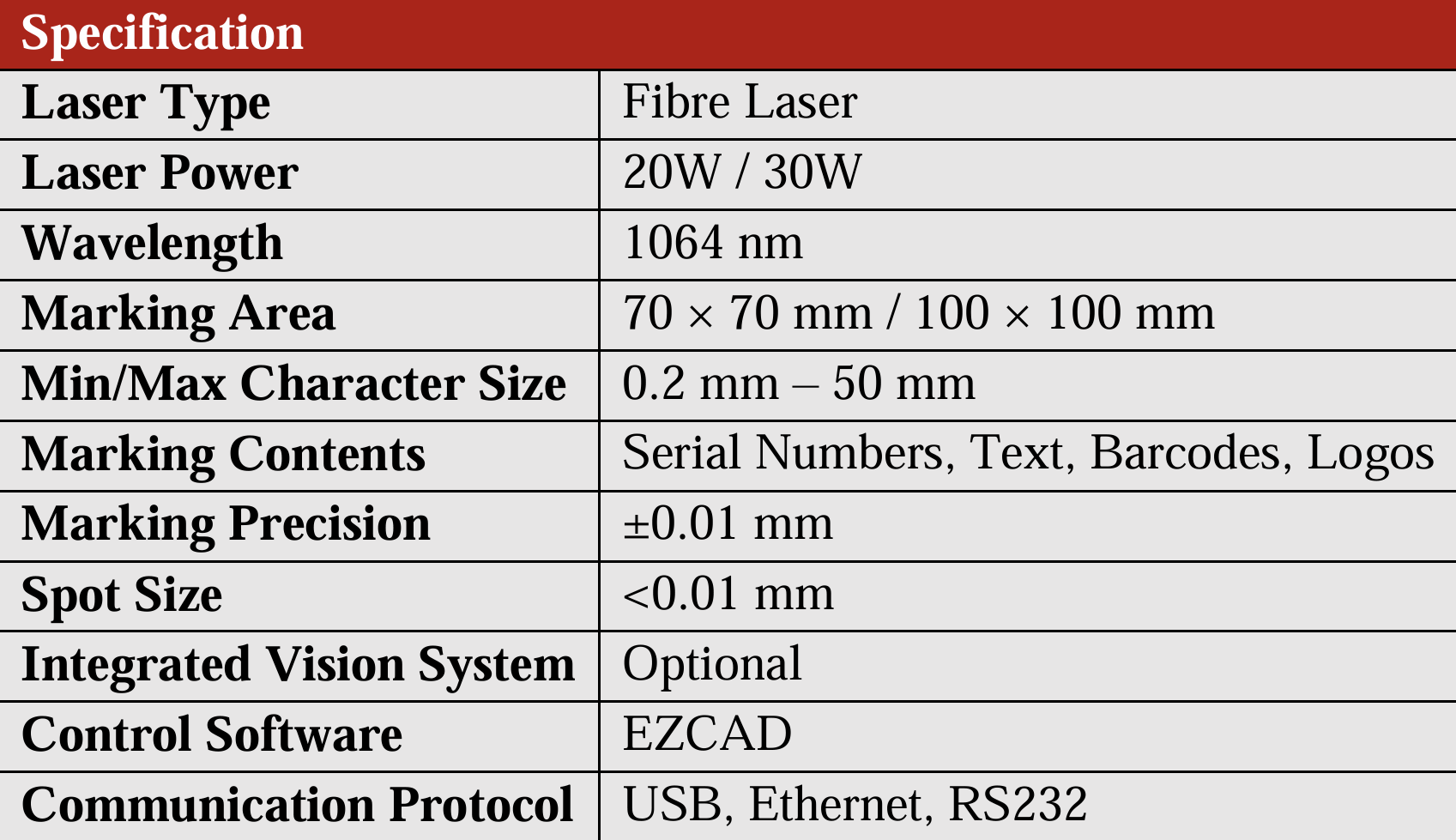

The SLS-MB Series Fiber Laser Marker is designed for businesses looking for a compact, efficient, and high-performance marking solution. Built to deliver exceptional results on metals and coated materials, this system is perfect for engraving barcodes, serial numbers, logos, QR codes, and deep markings at high speed with pinpoint accuracy. Engineered with a robust galvo head and stable fiber source, it provides consistent, high-quality output with minimal maintenance.

• Compact Design: Space-saving and ideal for small workshops or integrated setups.

• High-Speed Galvo Scanning: Delivers fast, stable marking performance for batch operations.

• Excellent Beam Quality: Produces sharp, high-resolution marks with fine detail.

• Low Maintenance: Durable fiber source with minimal upkeep and no consumables.

• Versatile Material Compatibility: Easily marks stainless steel, aluminum, copper, and coated metals.

• Plug & Play Operation: Simple setup with user-friendly software and smooth connectivity.

Applications: Surgical tools, electronic components, watch parts, connectors.

.jpg)

.jpg)

.jpg)

.jpg)

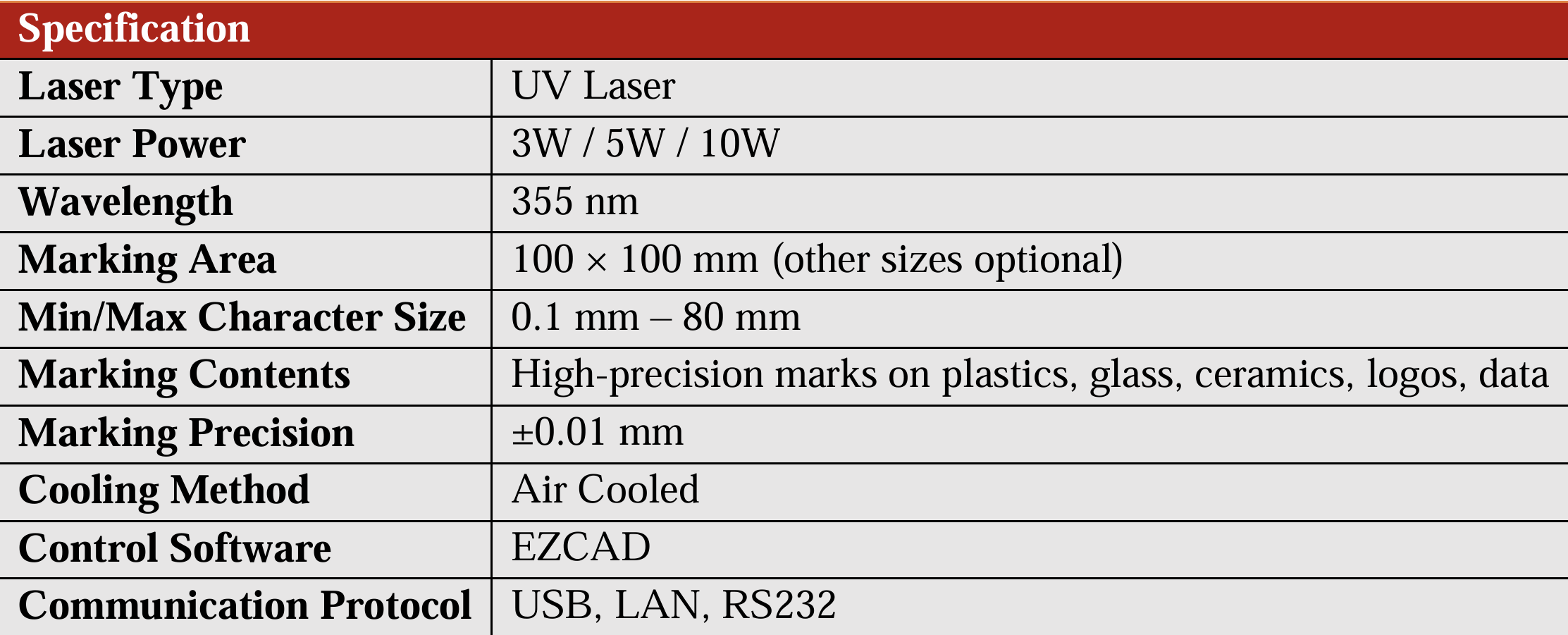

The SLS-MU Series UV Laser Marker is designed for ultra-precise, non-thermal marking on sensitive materials where heat damage is not an option. Using a 355nm wavelength, it ensures low heat impact and micro-level precision, making it ideal for industries that demand high contrast, high-resolution markings without compromising material integrity. Whether you're working with plastics, glass, ceramics, or electronic components, the SLS-MU delivers superior results with clean, crisp marks and consistent reliability.

• Cold Marking Technology: 355nm UV wavelength minimizes thermal stress, ensuring zero material distortion.

• Superior Fine Marking: FIdeal for micro text, intricate patterns, and high-precision 2D codes.

• Non-Contact & Non-Destructive:Perfect for marking delicate surfaces like PCB boards, medical plastics, and glass.

• High Contrast Output: Provides sharp contrast even on transparent or dark-colored materials.

• Minimal Maintenance: Reliable solid-state laser source with long operational life and minimal wear.

• Compact & Ergonomic:Fits easily into tight spaces or production lines without major modifications.

• Intuitive Software Interface: Seamless control with advanced marking features and batch management.

Applications: Medical plastics, smartphone components, printed circuit boards (PCBs), glassware, ceramics, cosmetic packaging, high-end electronics.

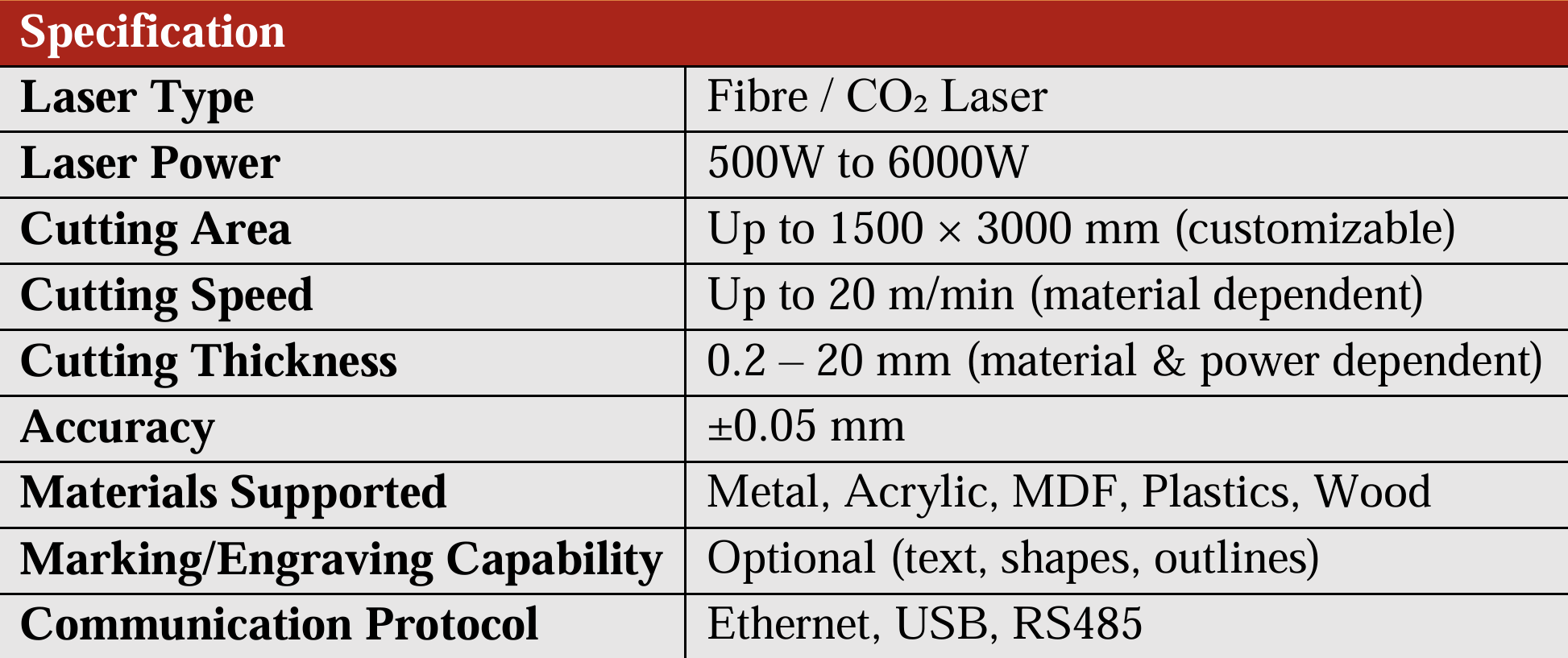

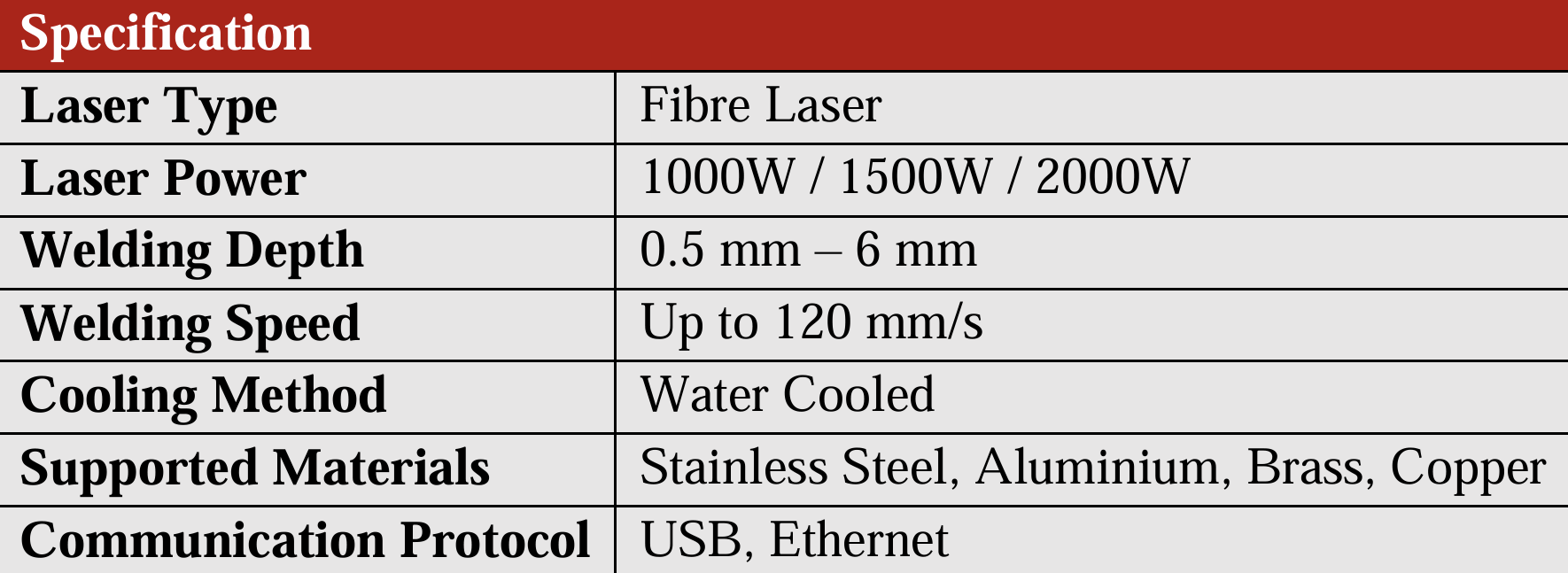

High-Precision Laser Solutions for Cutting and Welding Metal with Speed and Accuracy

Our Laser Cutting & Welding Machines offer precise, efficient, and high-speed metal processing solutions. Designed for industrial-grade performance, these machines excel at cutting complex shapes and welding with minimal heat distortion. Ideal for automotive, aerospace, and manufacturing sectors, they combine advanced laser technology with user-friendly controls for superior productivity and accuracy.

• High Precision Cutting & Welding: Delivers clean, accurate edges and strong welds with minimal distortion.

• Advanced Laser Technology: Utilizes state-of-the-art lasers for fast, reliable metal processing.

• Versatile Material Compatibility: Works efficiently with steel, aluminum, copper, and more.

• Robust Build Quality: Engineered for durability in demanding industrial environments.

• User-Friendly Interface: Intuitive software simplifies programming and operation.

• Energy Efficient: Optimized for low power consumption and sustainability.

• Compact Footprint: Space-saving designs suitable for small and large production setups.

Applications: Sheet metal fabrication, electrical panels, signage, enclosure manufacturing, Battery cells, electrical contacts, sensors, automotive assemblies.

Laser Welding

Laser Cutting

Custom-Built Laser Machines Tailored to Your Unique Manufacturing Needs

.jpg)

.jpg)

.jpg)

Our Special Purpose Machines (SPMs) are tailor-made solutions engineered to meet unique manufacturing challenges. These custom-designed machines integrate laser marking, cutting, welding, and other automation technologies to improve efficiency, reduce manual intervention, and enhance product quality. Perfect for specialized industries requiring precise and repeatable processes.

• Custom-Engineered Solutions: Designed to meet specific production needs and challenges.

• Integrated Automation: Combines multiple laser processes for streamlined workflows.

• High Precision & Repeatability: Ensures consistent output with minimal errors.

• Robust & Reliable: Built for continuous industrial use with low downtime.

• User-Friendly Controls: Simplifies complex tasks through intuitive software interfaces.

• Flexible Configurations: Adaptable for various industries and product types.

Genuine High-Quality Spare Parts to Keep Your Laser Systems Running Smoothly

.jpg)

.jpg)

.jpg)

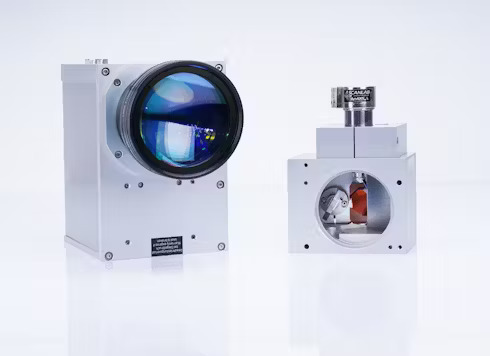

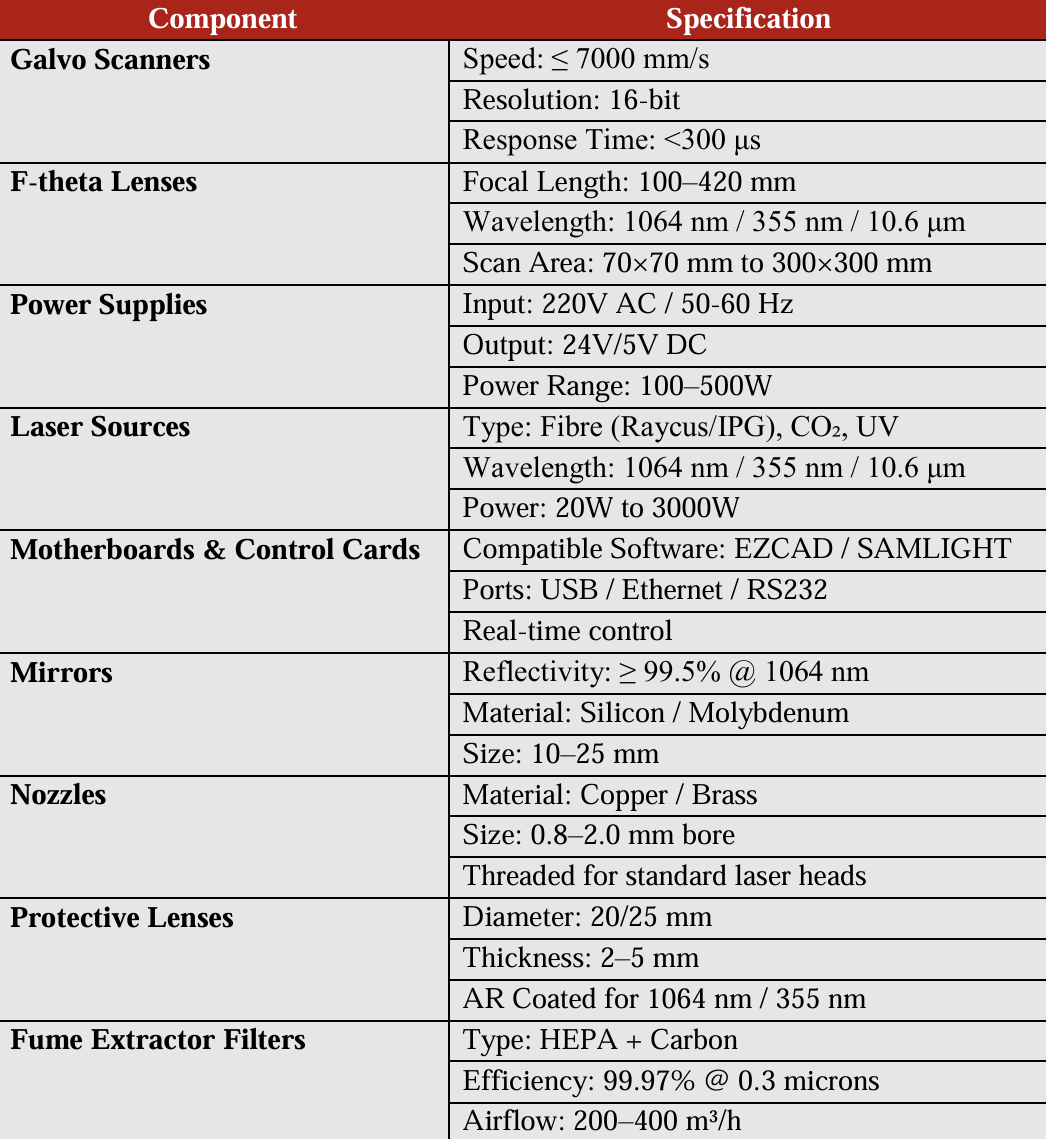

We provide a comprehensive range of Additional & Spare Parts to ensure your laser systems run smoothly and efficiently. Our genuine parts maintain machine performance, reduce downtime, and extend equipment lifespan. From laser sources and optics to control components, we supply high-quality parts compatible with leading laser marking, cutting, and welding machines.

• Genuine Spare Parts: High-quality components that guarantee optimal machine performance.

• Wide Compatibility: Parts compatible with various laser cutting, welding, and marking machines.

• Durability & Reliability: Engineered to withstand industrial conditions for longer service life.

• Quick Availability: Fast delivery to minimize machine downtime.

• Cost-Effective Solutions: Helps maintain productivity without expensive repairs.

• Technical Support: Expert guidance for part selection and installation.

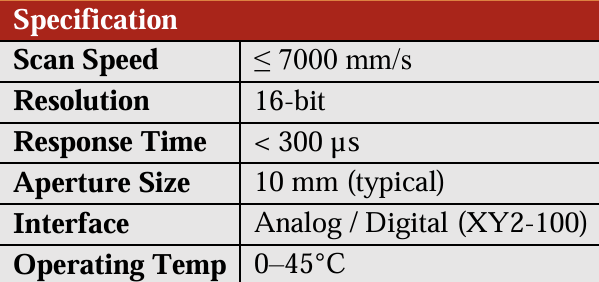

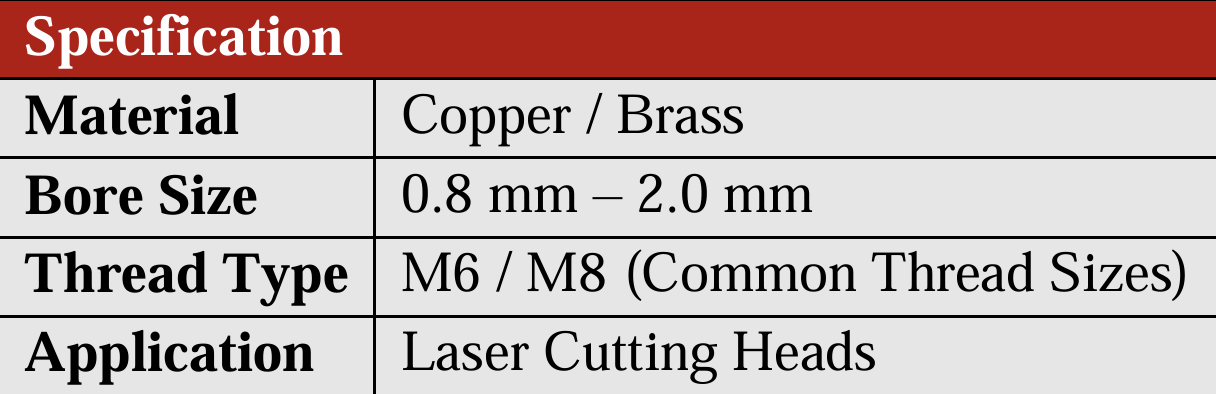

Galvo Scanners

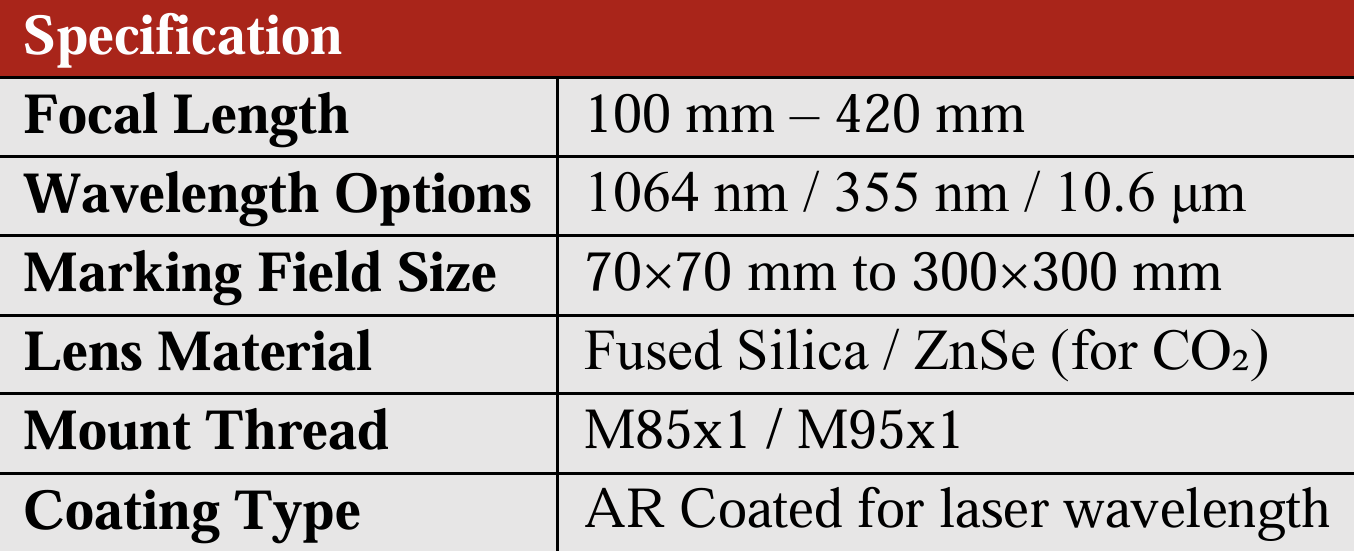

F-theta Lenses

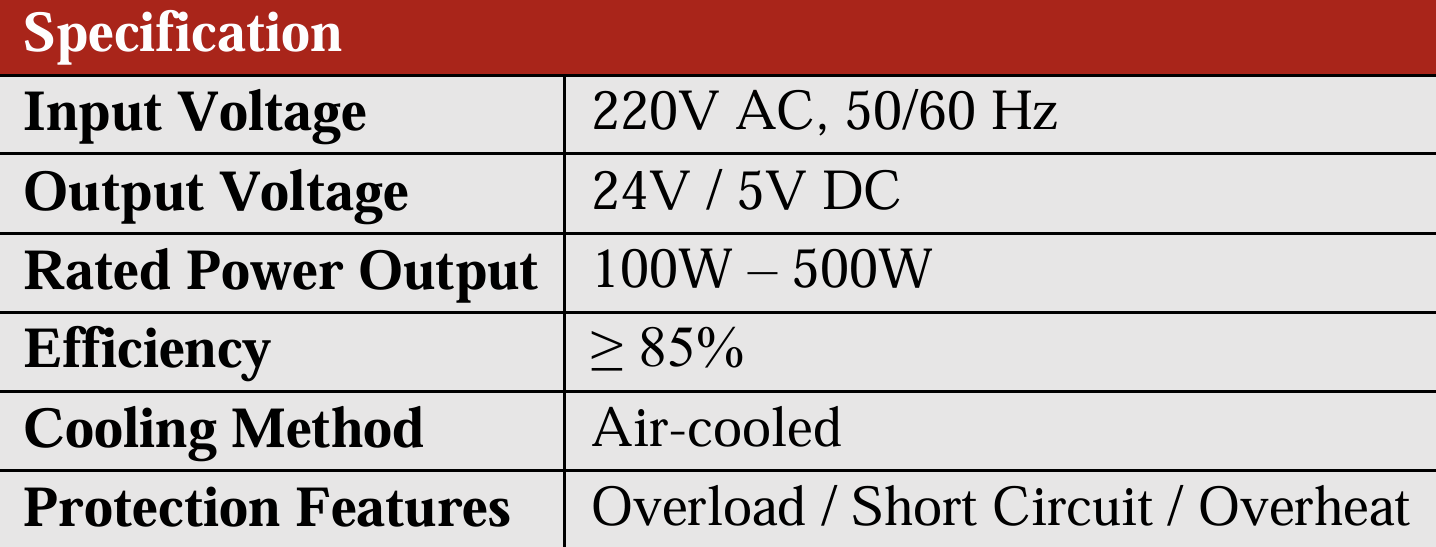

Laser Power Supplies

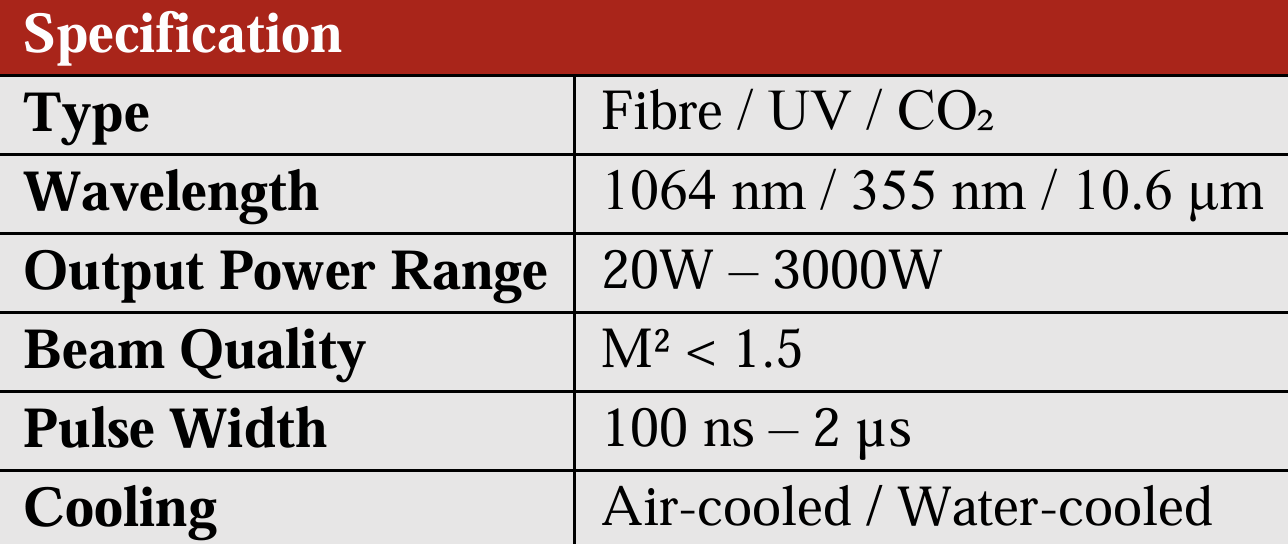

Laser Sources (Raycus / IPG / Others)

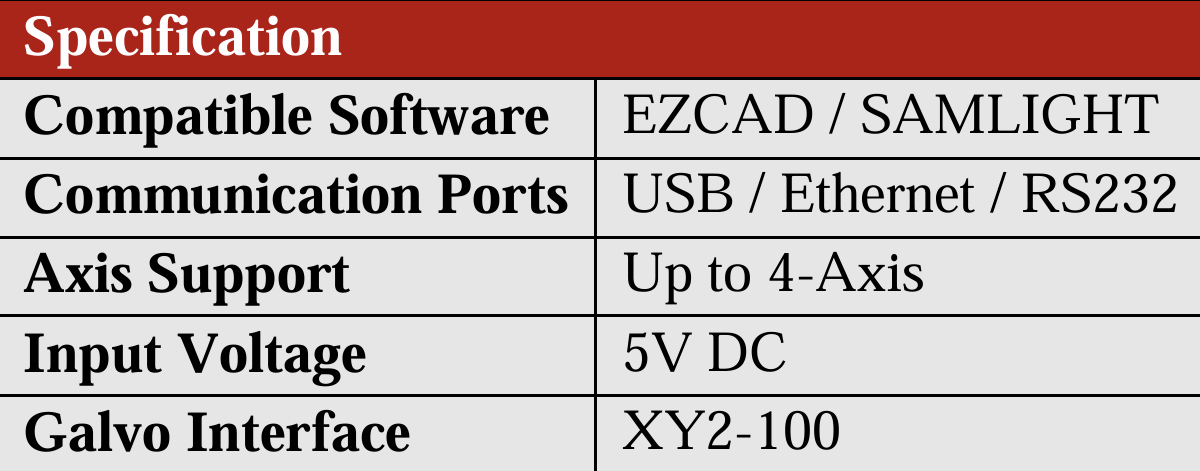

Motherboards & Control Cards

Mirrors

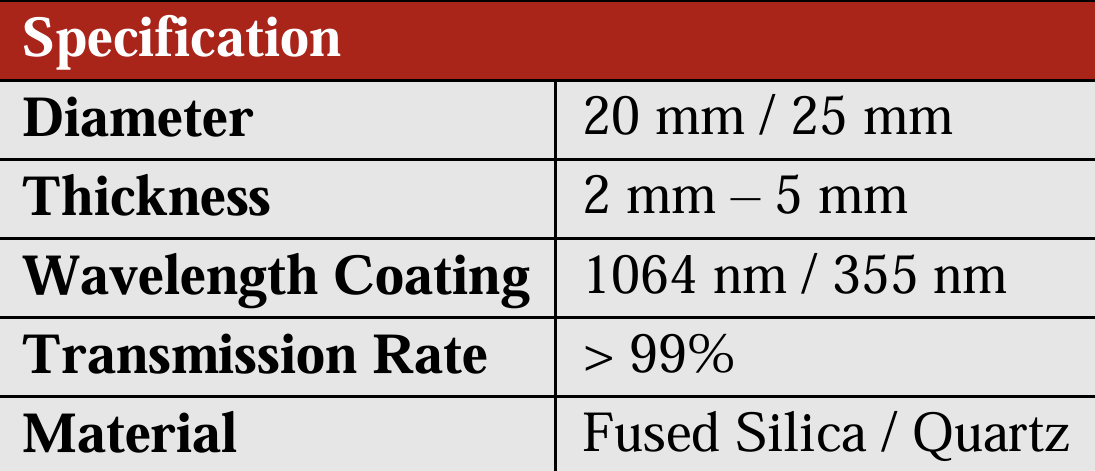

Protective Lenses

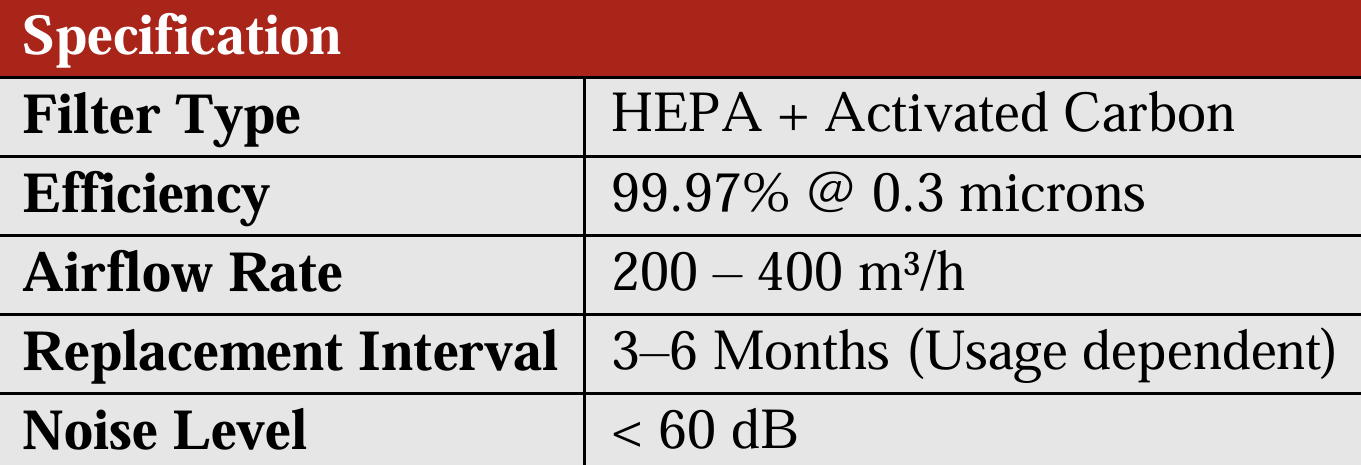

Fume Extractor Filters