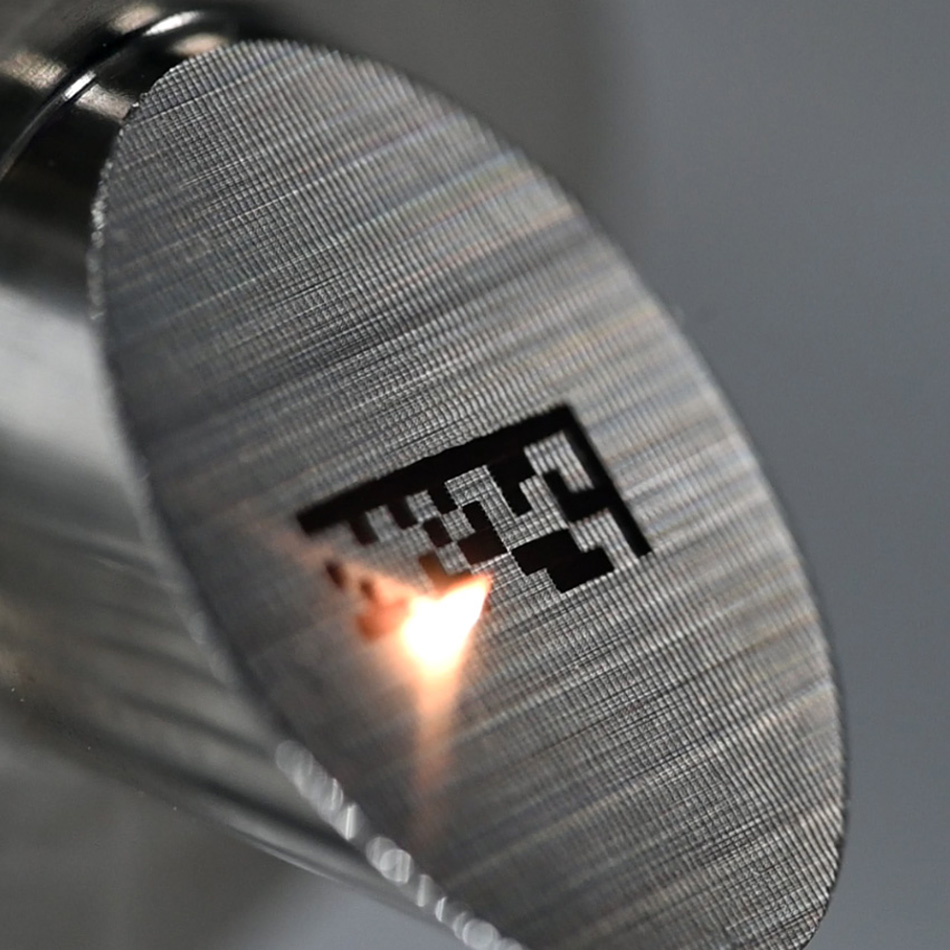

Laser technology is highly effective for marking, engraving, and cutting metals and alloys, offering unparalleled precision and versatility. Whether you are working with steel, aluminum, brass, copper, or precious metals, lasers provide high-quality results that are ideal for demanding applications.

Key Benifits:

- Permanent, High-Contrast Markings: Ideal for traceability, part identification, and serial number engraving.

- Minimal Material Distortion: Lasers offer non-contact processing, reducing the risk of warping or material stress.

- Corrosion Resistance: Laser markings on metals are highly resistant to wear and corrosion, ensuring durability even in harsh environments.

Common Applications: Automotive parts, aerospace components, medical devices, and industrial machinery.